The present engineering industries are rapidly moving to adopt Industry 4.0 approach. The element of automation is obvious in present engineering practices too. The motive of establishing the “Center of Excellence in Industrial Automation” was to make beneficiaries aware of the industrial automation which is the need of an hour. The beneficiary of this center will be students, faculties and people from industries. It would be the best solution to bridge between industry and academia. It surely helps to narrow down the gap between industry and academia. This will corroborate the theoretical knowledge with actual industry practices too!

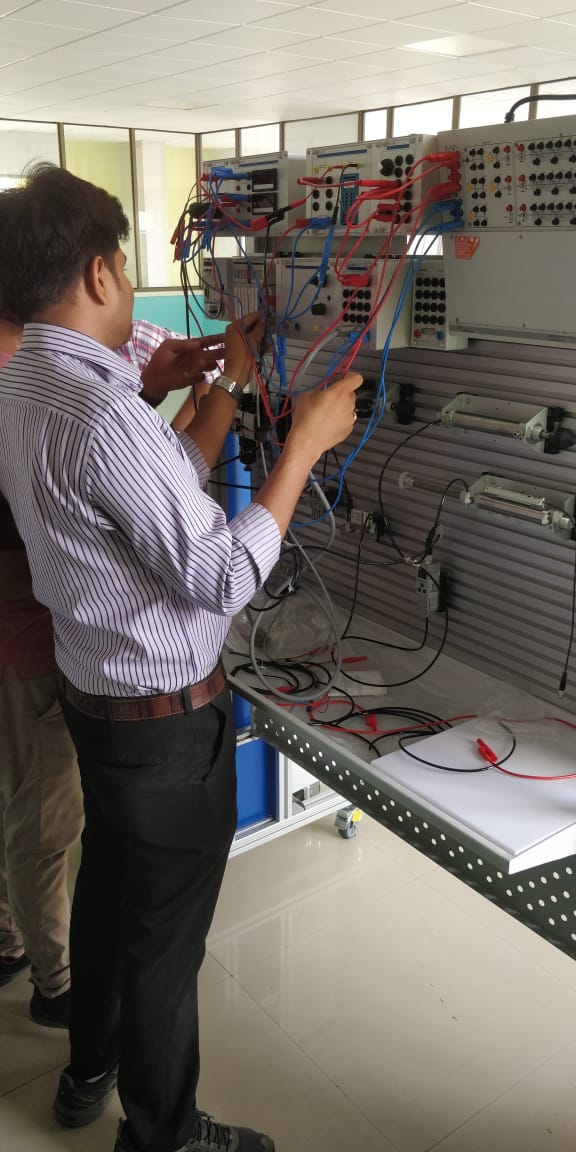

BOSCH-Rexroth group is competent and well known group for automation. It serves in wide spectrum of automation applications. BOSCH-Rexroth provides industrial automation training kits containing the scaled down model of actual application components and instruments. It is matter of proud for both BOSCH-Rexroth and Uka Tarsadia University to develop this center. The center also works on “Train the trainer” concept.

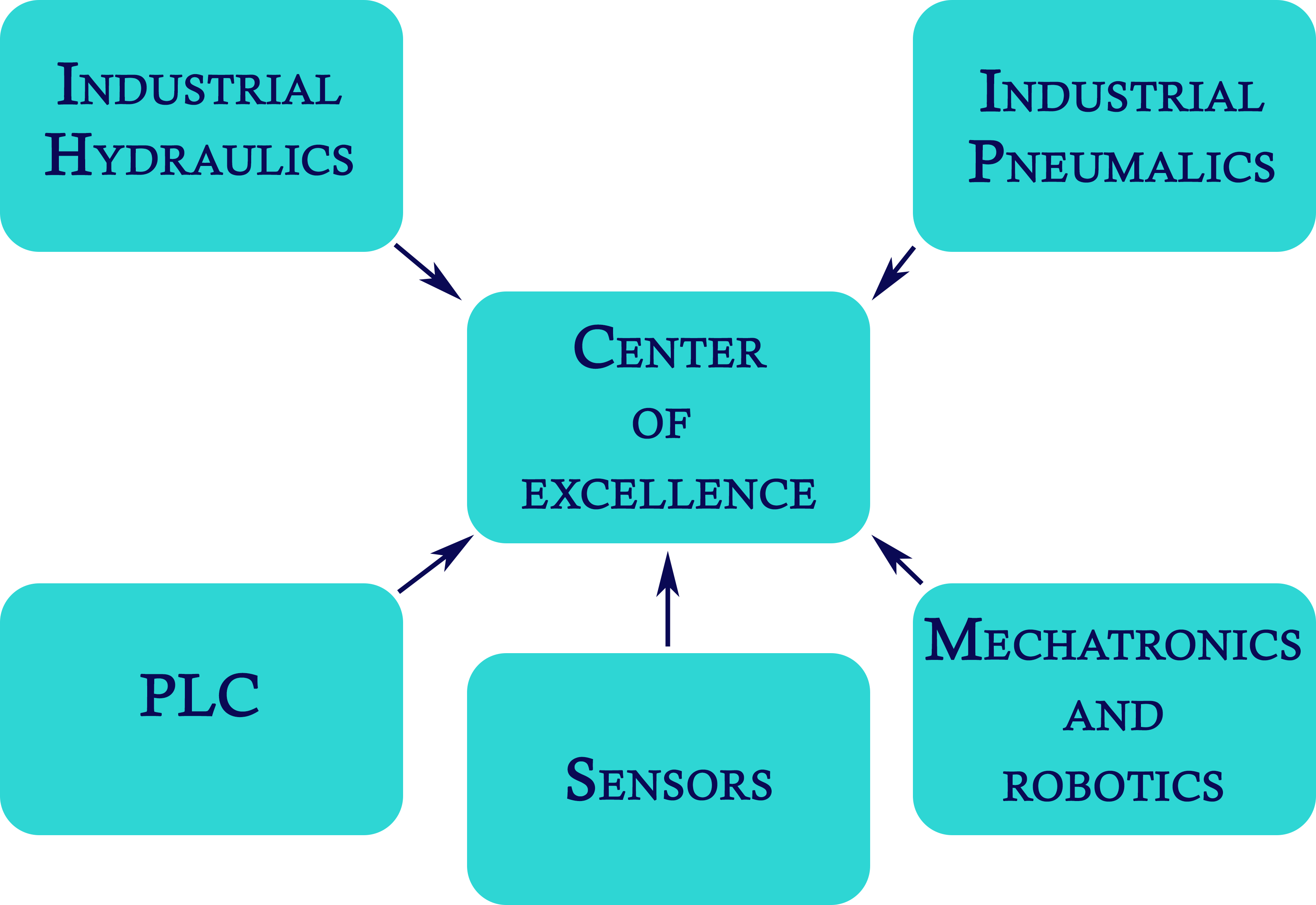

There are five different labs operating under “BOSCH Center of Excellence in Industrial Automation”. All labs are multidisciplinary. All labs are suitable for all the disciplines of Engineering at large. The highlight of each laboratory is as follows.

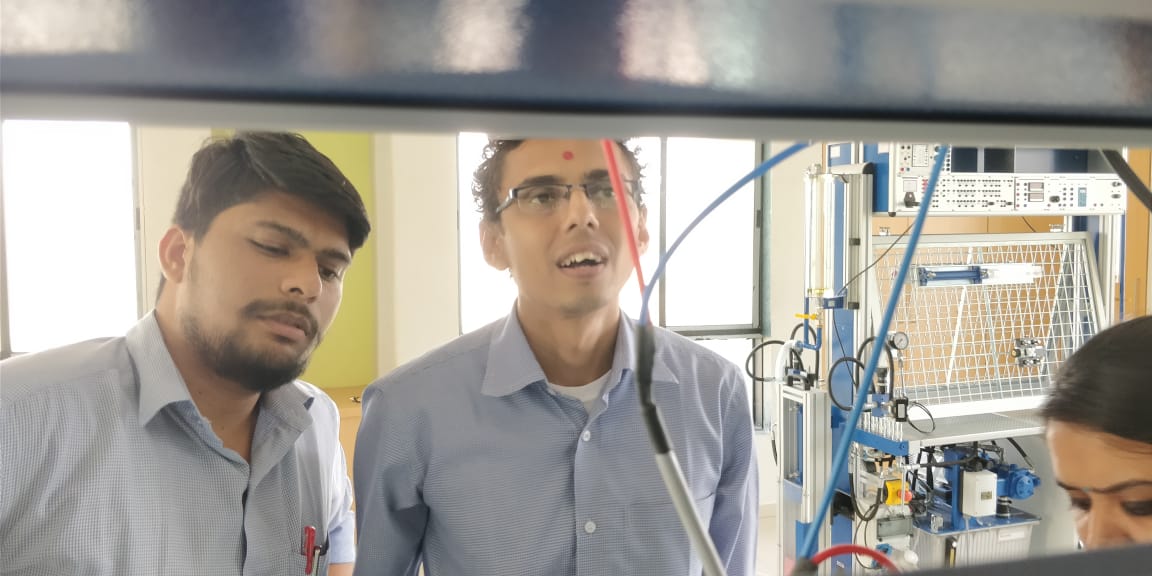

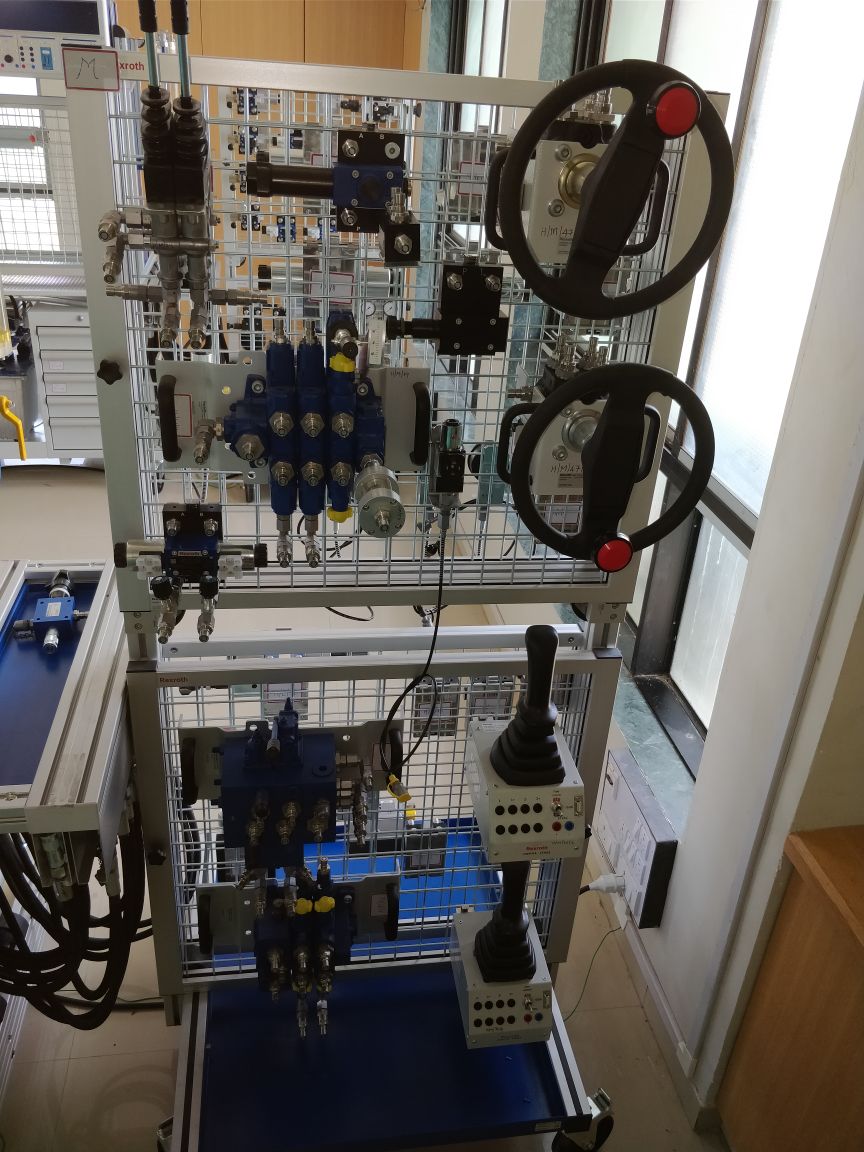

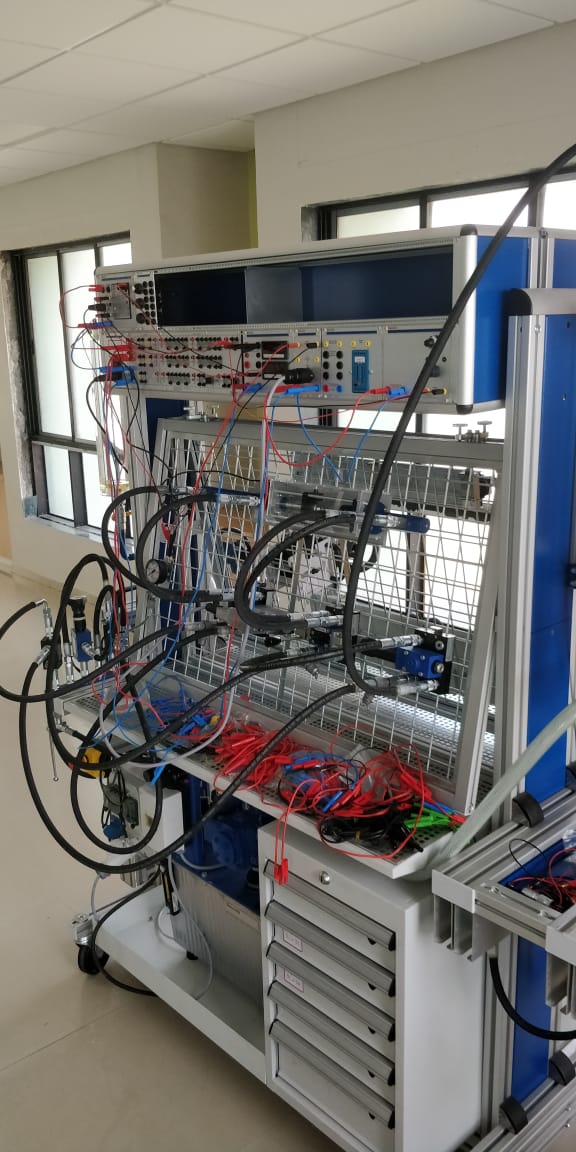

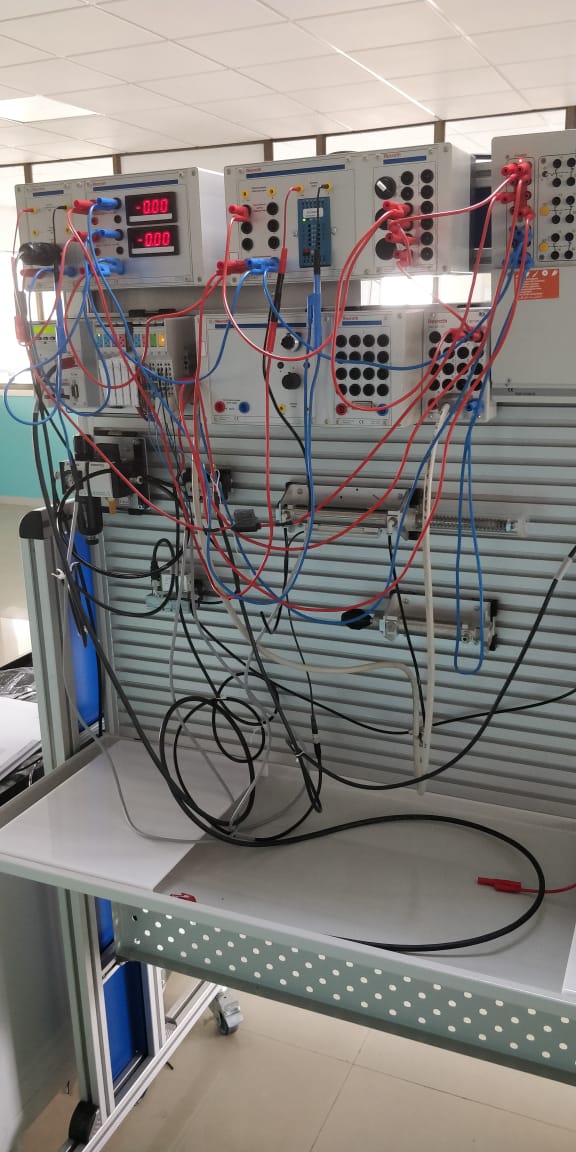

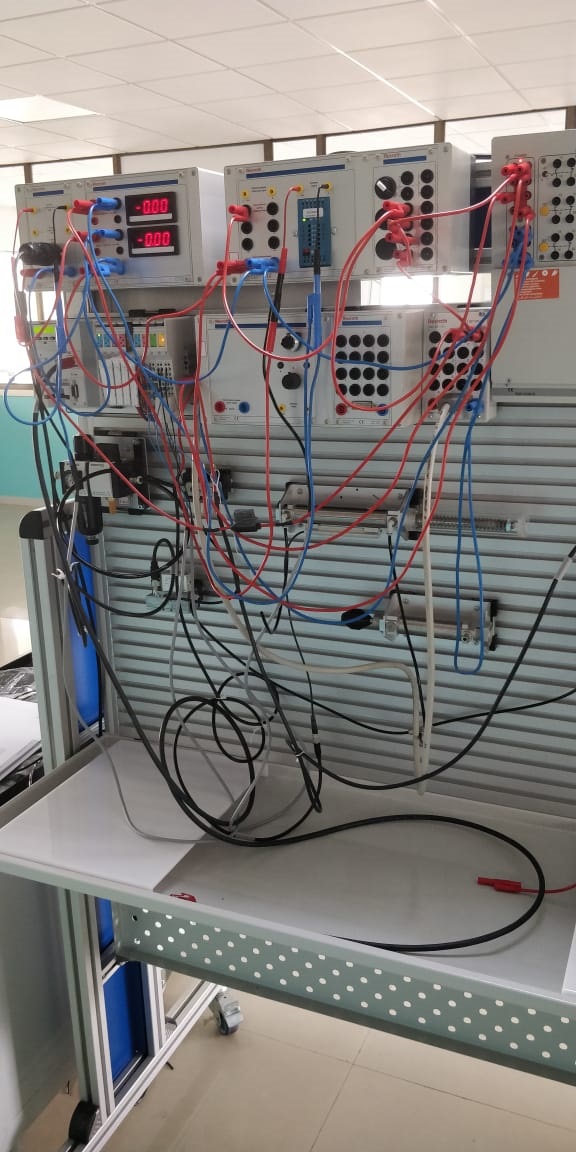

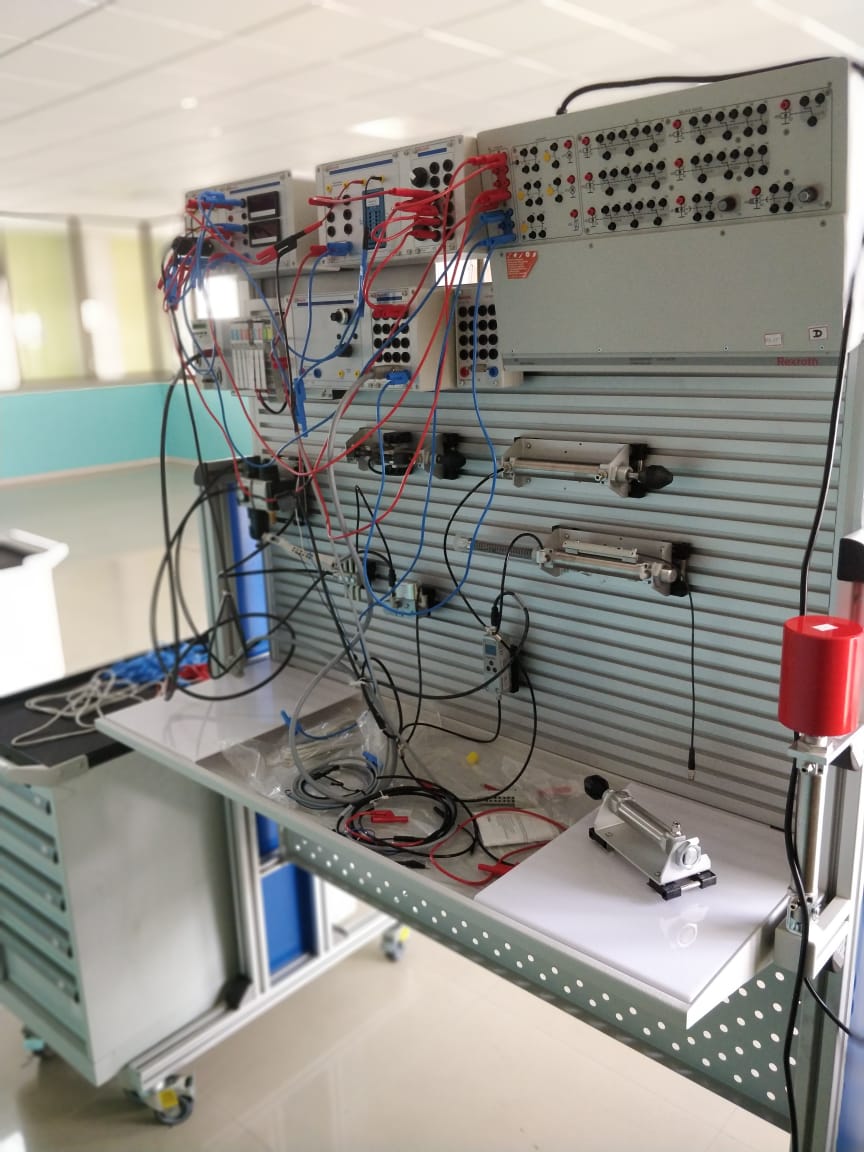

Industrial hydraulics laboratory :

Hydraulics-‘the power of liquid’ has wide applications in all engineering domains. No advanced mechanical systems can be imagined without hydraulics system. It has special characteristics of raising and lowering loads smoothly, undertaking linear or rotational movements, achieve acceleration or accurate positions, maintaining the preset speeds, transmitting the power or linking motion sequences. The mobile hydraulics and proportional hydraulics expands new horizons. It also amalgamates the PLC, sensors and other electronics within its domain. The beneficiary will work on the carefully designed exercising addressing industrial application. The following are glimpses of Industrial Hydraulics Lab.

- This covers the hydraulics system components (Direction control valves, piston-cylinder, pumps, etc…) understanding and their operations.

- To prepare the hydraulics circuits for different applications and experimentation of these circuits.

- Electro-hydraulics

- Mobile Hydraulics

- Proportional Hydraulics

- Available kits : 6

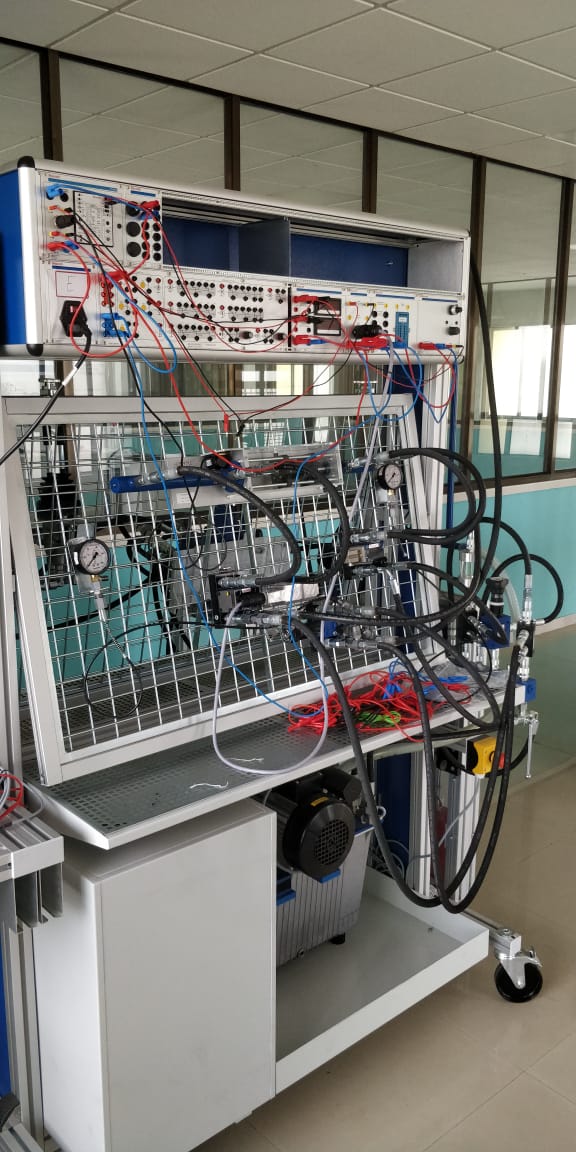

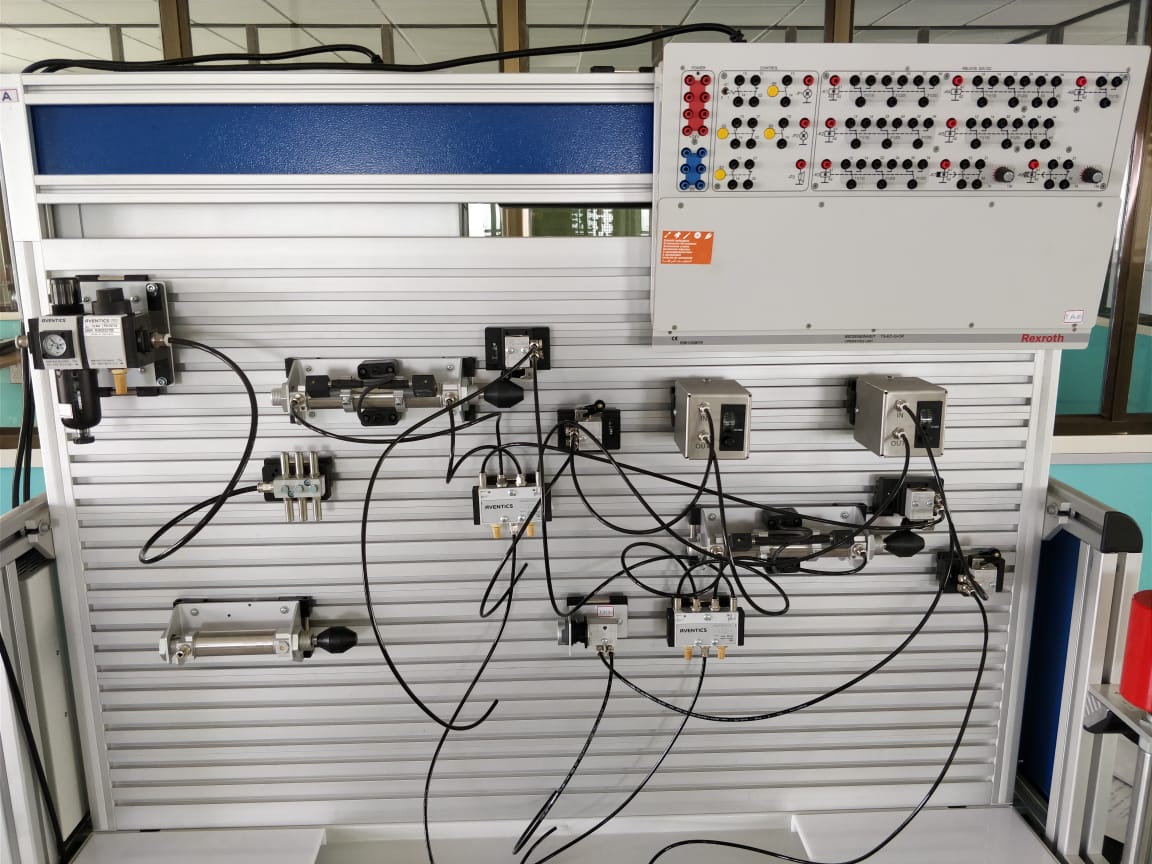

Industrial Pneumatics laboratory

Pneumatics-‘The power of compressed air’ is the art and science of turning the compressed air pressure to some useful work. The complex circuit with ISO symbols can result into numerous application that is being used in day to day life to the complex assemblies. The BOSCH Rexroth modular state of the art Pneumatic training system is based on standard components across the Bosch Rexroth product range. The center is equipped with the basic pneumatics and electro-pneumatics. A training system also comprises the PLC unit enabling the operating of Pneumatic system via PLC programming.

- This covers the pneumatics system components (Direction control valves, piston-cylinder, compressor, etc…) understanding and their operations.

- To prepare the pneumatics circuits for different applications and experimentation of these circuits.

- Electro-pneumatics

- Available kits : 6

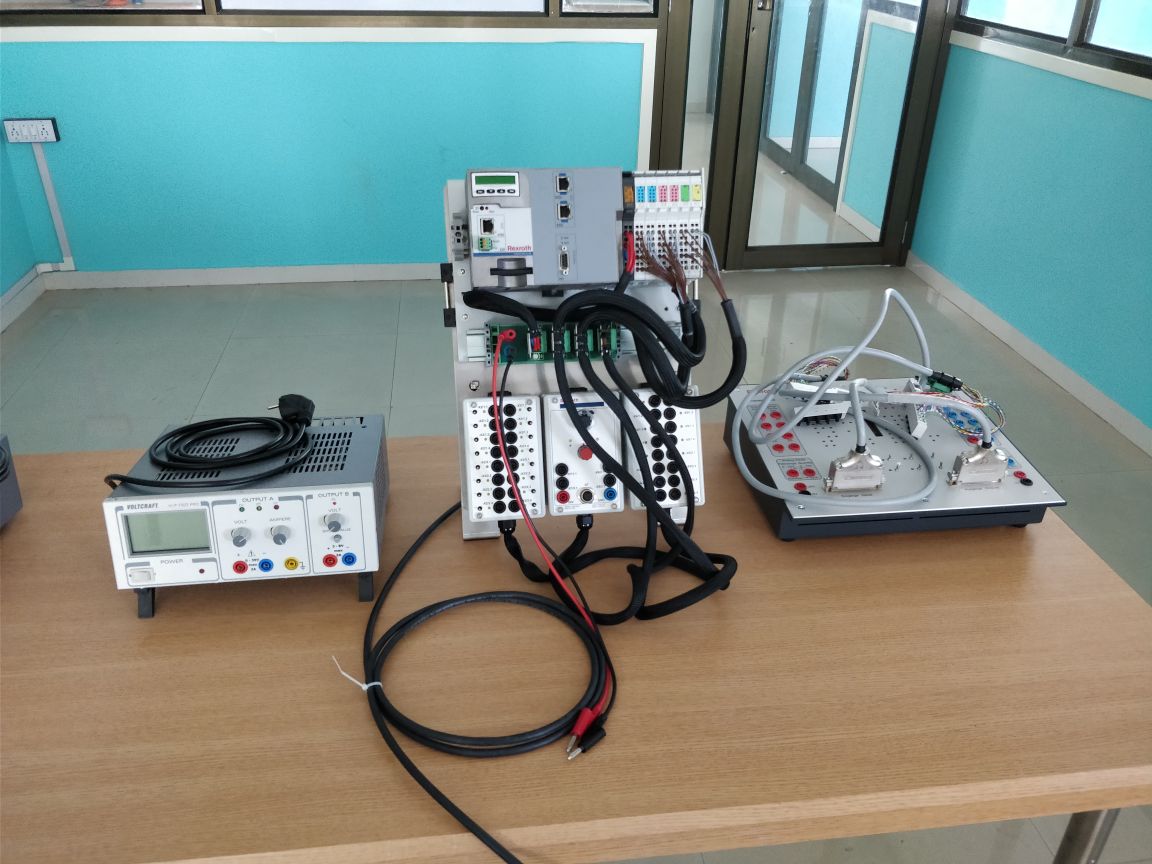

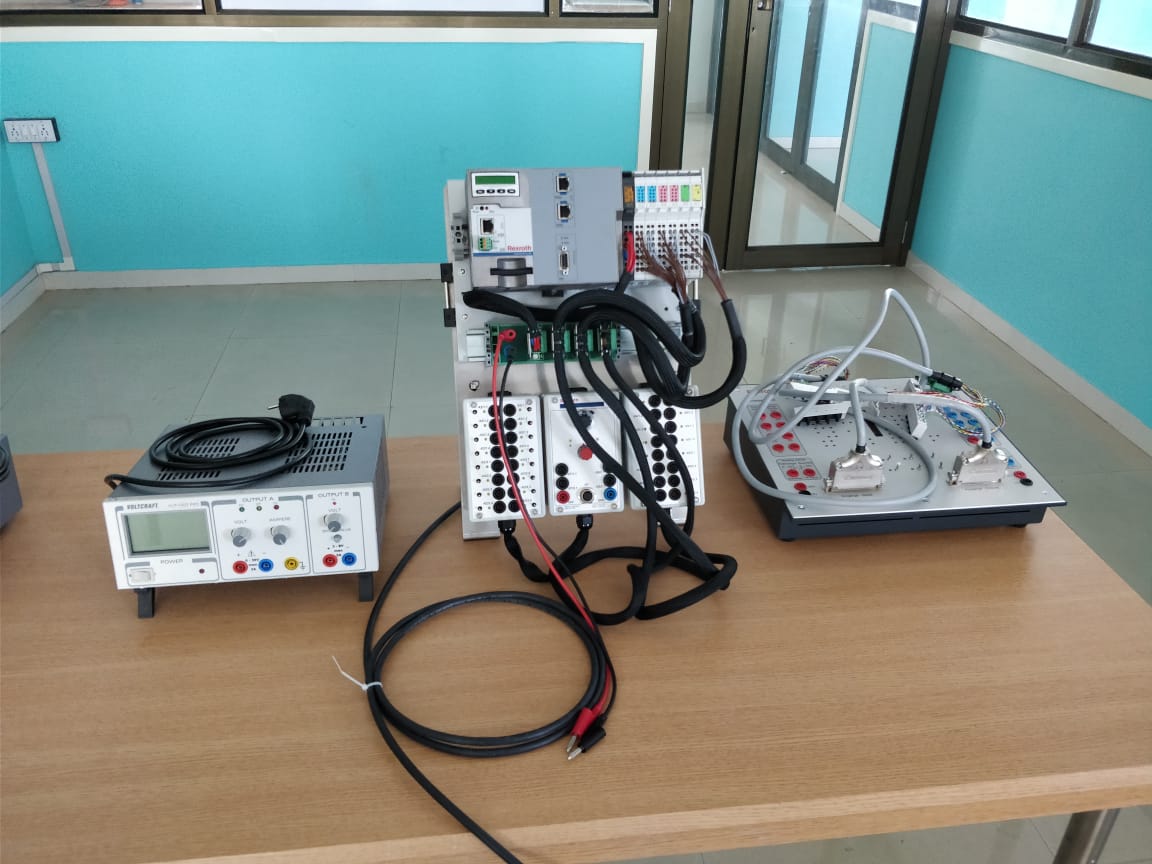

Programmable Logic Control (PLC) laboratory

As name suggests, logic enables human smarter and efficient. It is the process which receives information via sensor signals and sends the output signals to the systems attached to the PLC unit. This is the essential element of automation. The automation is achieved by PLC. It can be used to manage extreme conditions. Be it fast, slow, small, big, cold, hot or any danger situations for human. The powerful Bosch Rexroth PLC trainer system has Analog I/O which could be used to test PID loops and other variable functions. The L20 PLC controller may be connected via an Ethernet Switch with external devices, which can be used to learn the ability to program both products from a single ethernet connection. The ethernet switch has extra ports which can be used to connect additional HMIs, to demonstrate OPC connectivity to SCADA software.

- This covers the understanding of Programmable Logic Controller module, Programming languages of PLC like ladder diagram, functional block diagram, structured text, etc…

- Indraworks software training (Basic and advanced)

- Interfacing with sensors, hydraulics and pneumatics system with Human Machine Interface

- Available kits : 6

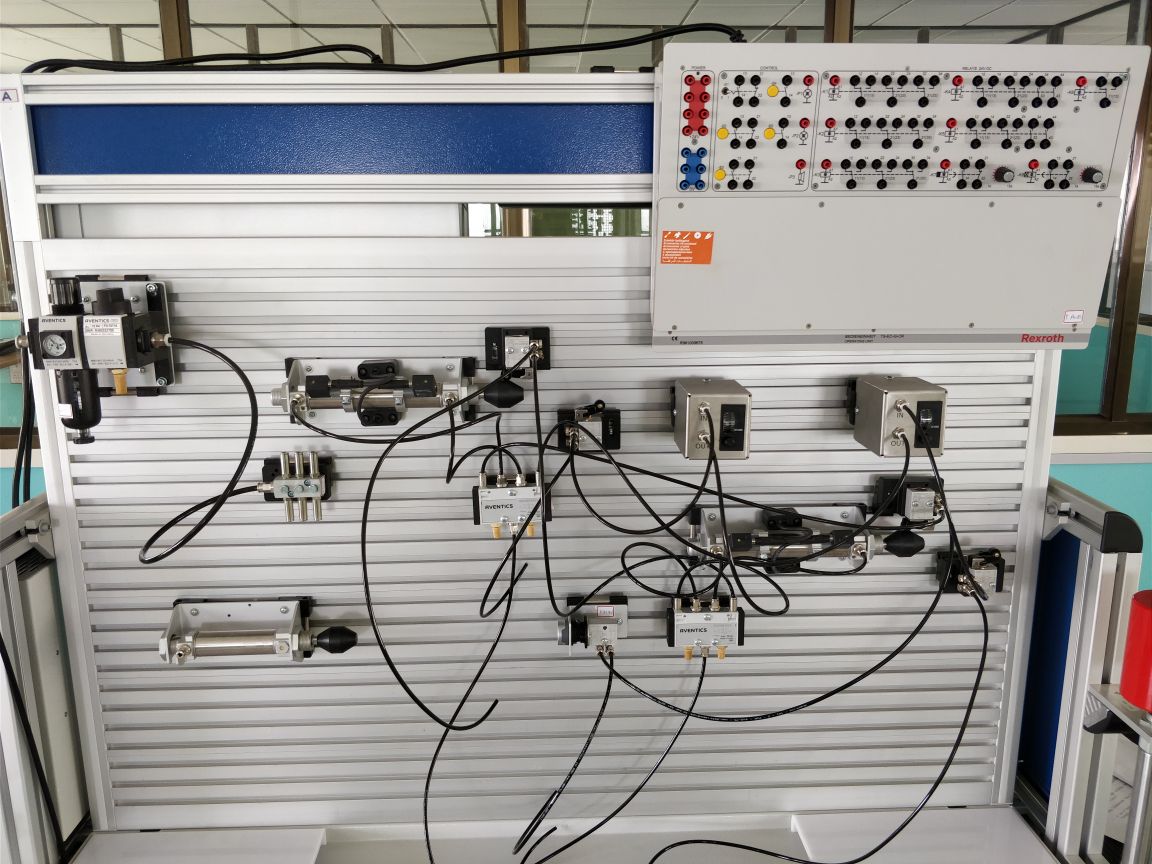

Industrial sensors laboratory

Sensor Technology has emerged as a key technology to deploy Industrial Automation solutions. Scientific and technical innovation is now increasingly linked with the term sensor. There are few problems today in data acquisition that cannot be solved using sensors. For that reason, sensors occupy a prime position in the broad field of factory automation and in many other applications like in construction, utilities, building management and office equipment etc. BOSCH Rexroth sensorics trainer, fitted with Pepperl & Fuchs industrial sensors, provides opportunity to work on practical exercises and gain specialized technical knowledge about characteristics of each sensor.

- This covers different types of commercially available sensors understanding.

- Proximity sensors (Inductive, capacitive, magnetic, ultra-sonic, photo-electric types)

- Interfacing with other modules.

- Experimenting the suitability sensors in typical applications.

- Available kits : 6

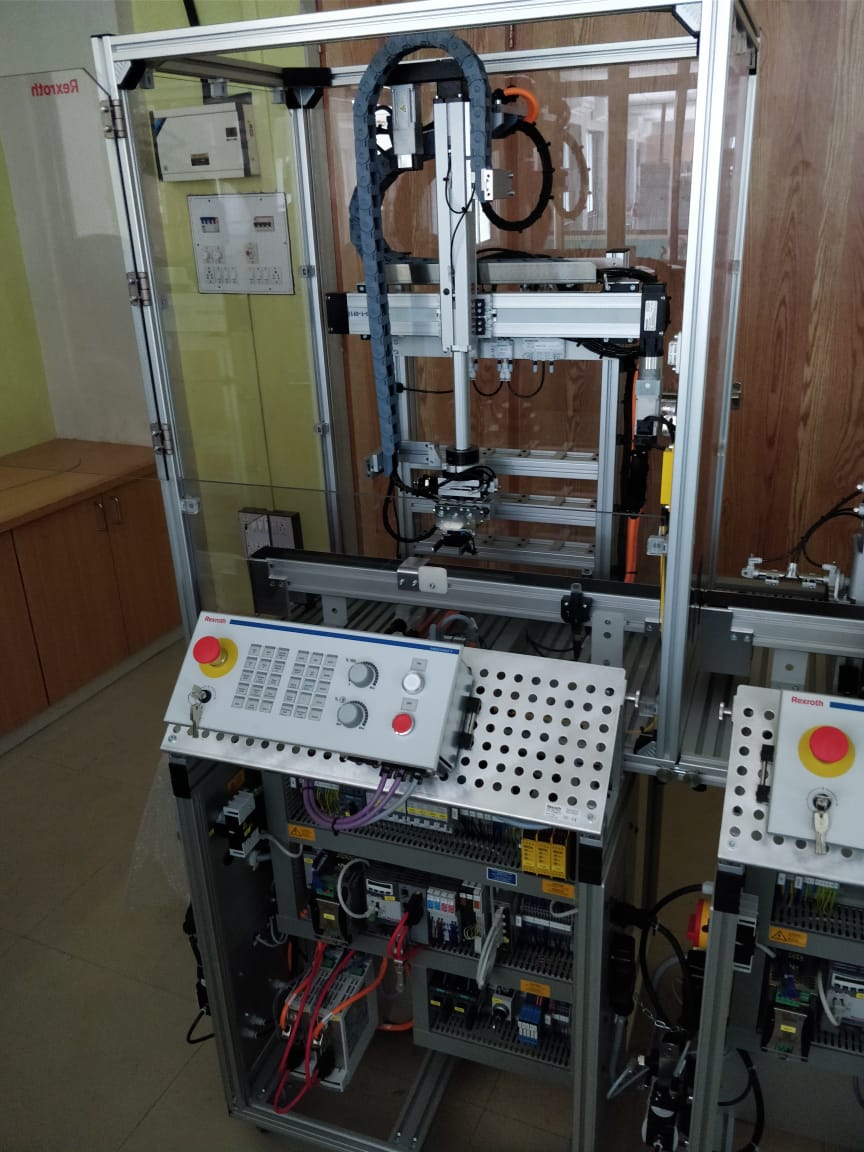

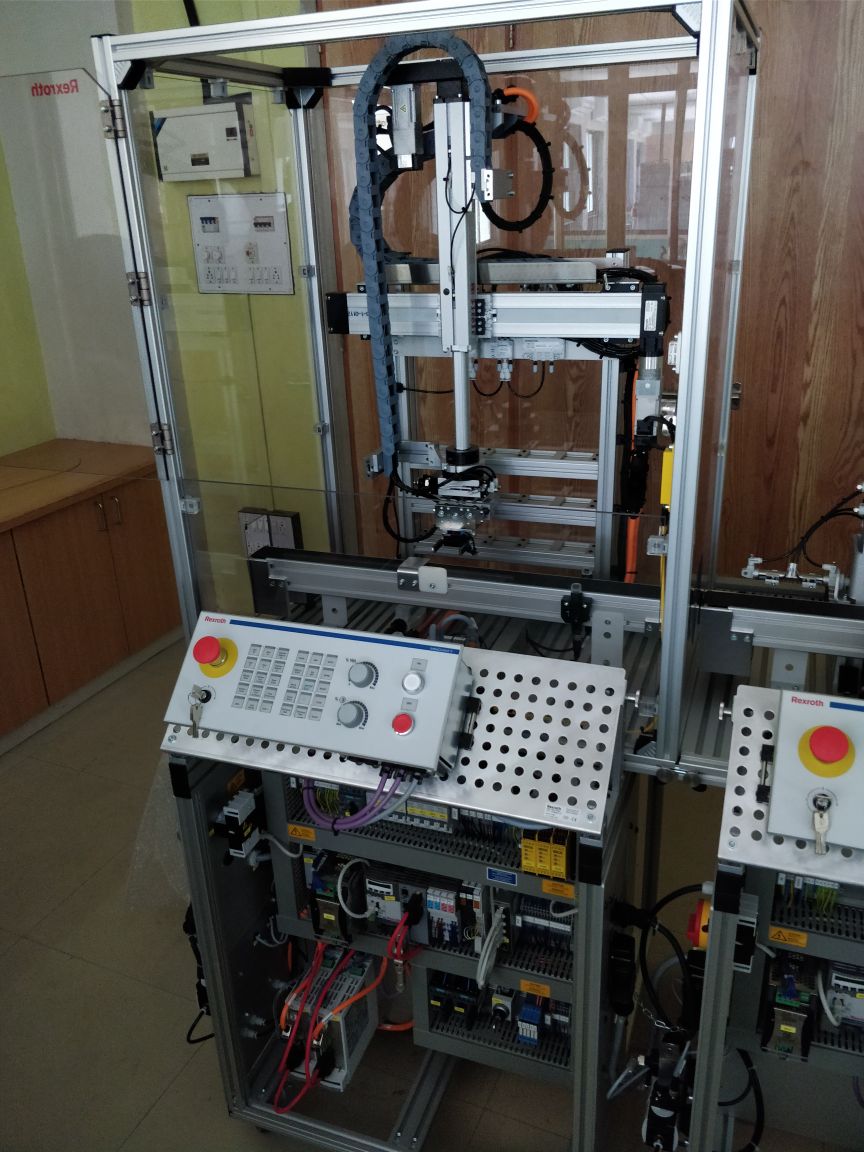

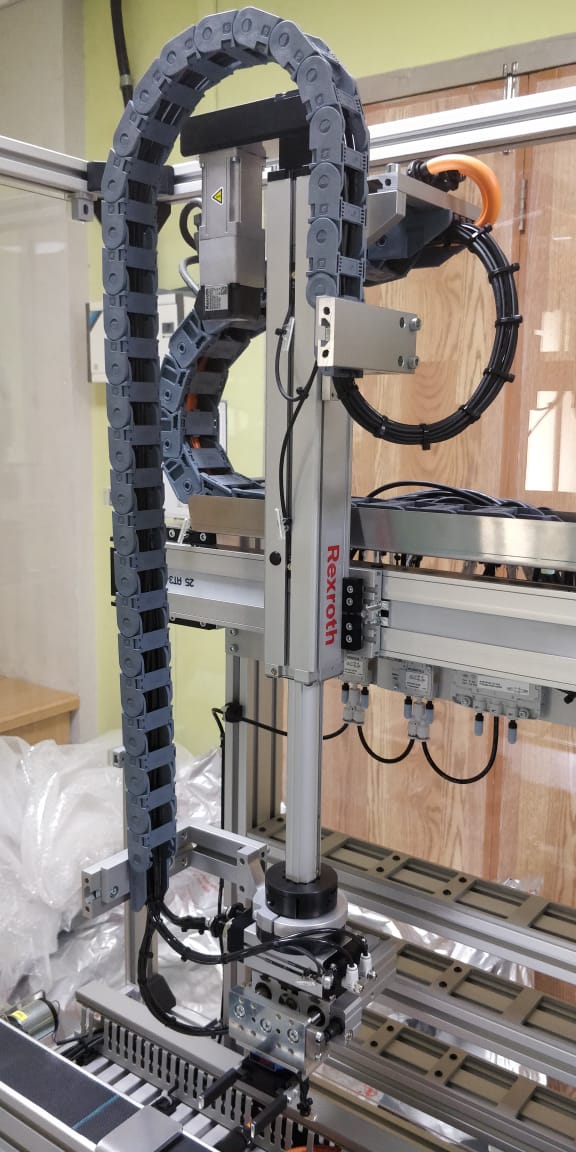

Industrial Mechatronics and robotics.

A system is a reprogrammable, multifunctional manipulator designed to move material, parts, tools, or specialized devices through variable programmed motions for the performance of a variety of tasks. It is a mechanical device that sometimes resembles a human and is capable of performing a variety of often complex human tasks on command or by being programmed in advance. The existing system is to assemble three parts and placing it into empty racks. There are 3 stations. Each station can be programmed separately as well as in connection to one another. There are several sensors and pneumatic actuators in each station to perform the specific task. This is the place where all branches can work.

Uka Tarsadia University is committed to provide quality education. This center of excellence is giant step to bolster the fundamental knowledge of various engineering applications. This will help a lot to prepare industry-ready students. Hence this will motivate “Skill India” too!